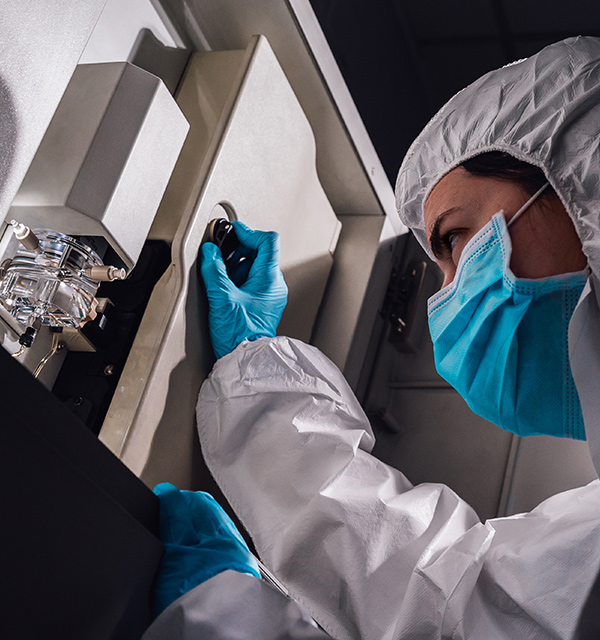

Cleanroom Environmental Monitoring Services

Environmental Monitoring

What is Cleanroom Environmental Monitoring?

Cleanroom environmental monitoring is created and regulated by the FDA/USP with set parameters that need to be adhered to. State Departments follow the environmental cleanroom standards and perform inspections based on these regulations. Our team stays up to date on the changing guidelines for FDA/USP/cGMP cleanrooms.

ISO Classifications are determined by your cleanroom process. For example, a medical device laboratory following EU regulations will follow the ISO 8 regulations for clean production; a hospital pharmacy will follow ISO7 and ISO5 regulations for aseptic processing of CSP's (ISO 8 is acceptable for an anteroom that does not have a shared ISO7 negative and ISO7 positive Cleanroom); semi-conductor facilities will follow ISO5 regulations to ensure minimal dust particles for production. At Cleanetics, we first ask what your process is and develop an environmental monitoring program to meet your regulated certification requirements.

Cleanroom Environmental Monitoring is Vital.

Maintaining cleanrooms with an environment that meets stringent standards is crucial.

At Cleanetics, we specialize in Cleanroom Environmental Monitoring, ensuring that your cleanroom meets and exceeds regulatory requirements. FDA, State, DOH, and JCAHO require environmental monitoring and proper documentation to adhere to the regulations set forth by these entities. These regulations are set in place to validate product integrity and staff SOP for operation and safety.

Cleanetics will work closely with your team to review regulations, conduct the proper ISO-14644 testing. We are CPT Cleanroom Professionals, NEBB Certified for balancing, ASHRAE, Eagleson Institute, & AAF International Certified.

Cleanroom Environmental Monitoring Services:

- Airborne Non-Viable Particle Testing

- Following ISO-14644

- Viable Air Impaction and Surface Sampling

- HEPA Testing & Certification

- Smoke Test Conducted

- Temperature and Relative Humidity Testing

- Pressure Differential Testing

- Immediate Rectification of balancing if not in compliance

- Cleanroom Balancing: Testing and Adjusting

- Bio-Safety/PEC/LAFW/Glovebox Certification

- Decontamination Process performed following Certification

- Tracer Gas Containment Testing

Monitoring Environments of Multiple Industries

- 503 A/B

- USP 797/800

- Medical Device

- Pharmaceutical & Biotechnology

- Semi-Conductor

- Cannabis

- Aerospace

Why Choose Cleanetics for Your Cleanroom Monitoring?

- Expertise in Compliance: Our team stays up to date on changing regulations and follows all set guidelines. Knowing your process and set cleanroom standards sets us apart from the rest.

- Advanced Monitoring Systems: We can provide real-time monitoring systems with continuous data logging, offering you peace of mind and real-time data on your cleanroom's environmental conditions.

- Comprehensive Services: Our services extend beyond monitoring. Whether you are renovating an existing space or building a new cleanroom, Cleanetics offers end-to-end solutions from consulting and planning to execution and validation.

Cleanetics provides a range of cleanroom consulting services, including:

- Consultative Review: Prior to the onset of the clean room design, we seek to identify any noticeable gaps or inefficiencies in the client's flow of production that could be mitigated or improved. Thus, Phase I of every clean room project begins with a Consultative Review by the Cleanetics Engineering Team. This helps us better understand our clients' historical processes, also known as "Means & Methods."

- Cleanroom Design: During our initial feasibility and constructability analysis, our team works closely with clients to design cleanrooms that meet their unique requirements. This includes assessing the client's needs, identifying potential risks and hazards, and developing a customized design that meets all relevant cleanroom standards. Most importantly, Cleanetics helps our clients to formally specify their Performance Criteria (environmental) and Operational Standards (SOPs & GMPs) to ensure that each clean room project has a clear direction from its conception to its certification.

- Cleanroom Testing, Validation, and Calibration: After the design process, Cleanetics provides cleanroom testing services to ensure the new cleanroom operates at peak efficiency. This step features particle counting, air flow analysis, temperature testing, humidity control, and more.

- Cleanroom Certification: Cleanetics' team of experts provides cleanroom certification services to ensure that the cleanroom meets all regulatory standards, including testing and certification for ISO 14644-1 and USP 797/800 compliance.

- Training and Education: Cleanetics offers training and ongoing education services to ensure your staff understands the importance of cleanroom operation and maintenance. This encompasses training on safety protocols, cleanroom procedures, and cleanroom best practices.

- Ongoing Support: Cleanetics is here for you with ongoing support to ensure your new cleanroom operates at peak efficiency and meets all regulatory standards.

Ready to Validate Your Cleanroom Standards?

If you're looking for a partner to help manage your cleanroom's environmental monitoring and more, look no further than Cleanetics. Learn how we can assist in optimizing your cleanroom for peak performance and compliance.