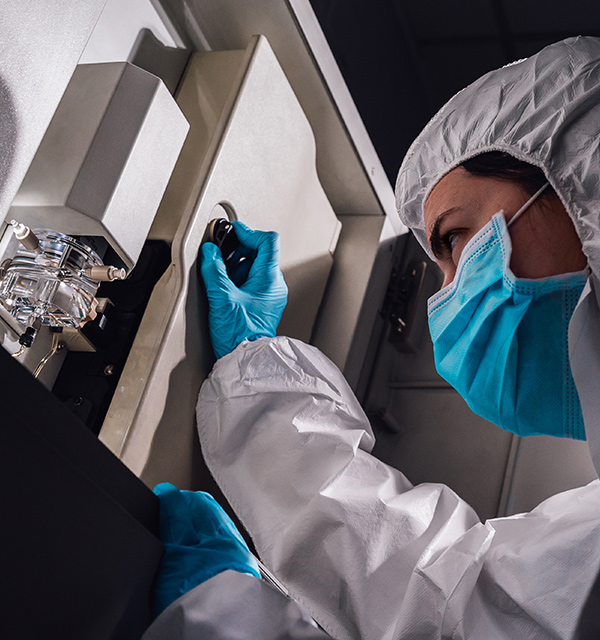

Medical Device Cleanroom Construction & Maintenance

Cleanrooms are Utilized for Making and Packaging Medical Grade Equipment Nationwide

Products that we see in the medical profession, whether on a shelf at the local pharmacy or used for surgery, are made and/or packaged in a cleanroom facility. For example, medical grade masks, gloves, medical PPE, sterile gauze packets, containers for medicine, knee replacement material, medical tubing, auto injectors for Epi-pens, Inhalers, etc., are all packaged in a sterile environment. If your facility is considering becoming a part of the medical device community, it is best to consult with Cleanetics to ensure your facility is compliant with industry specific regulations.

.jpg)